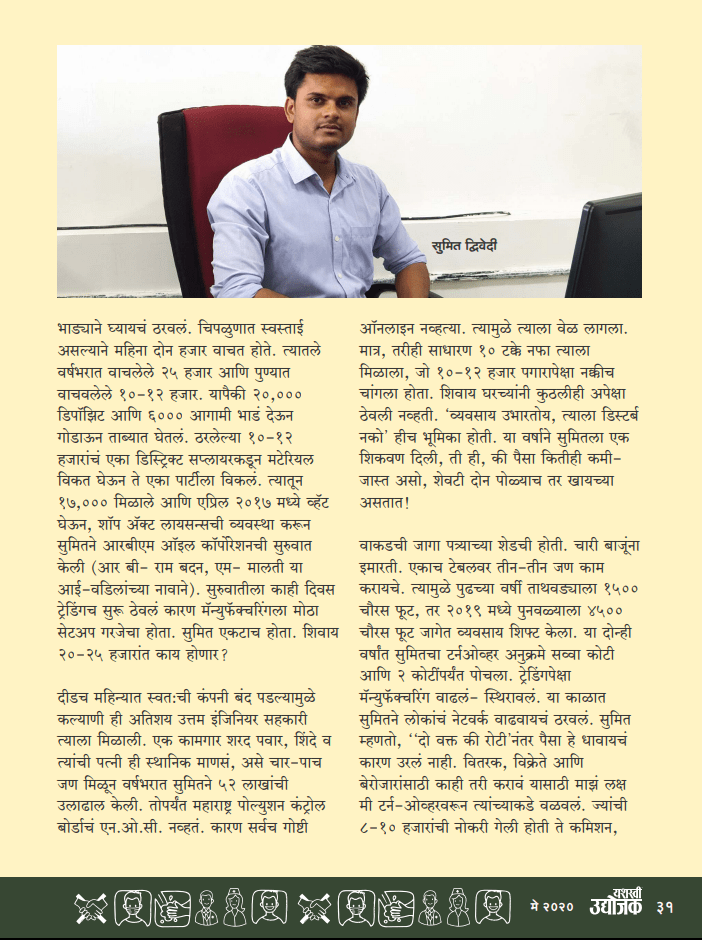

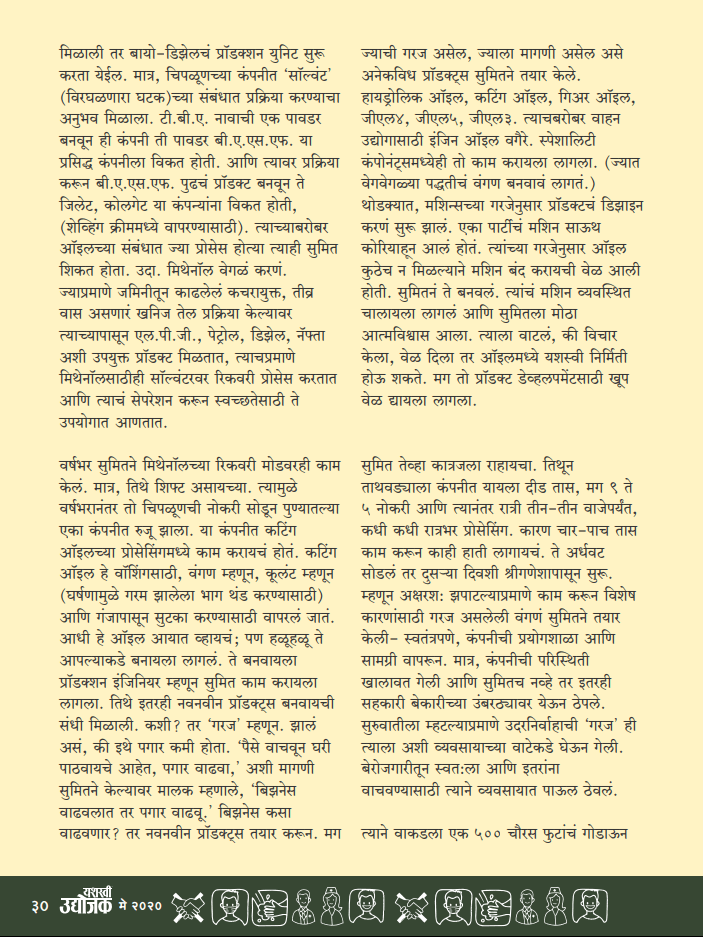

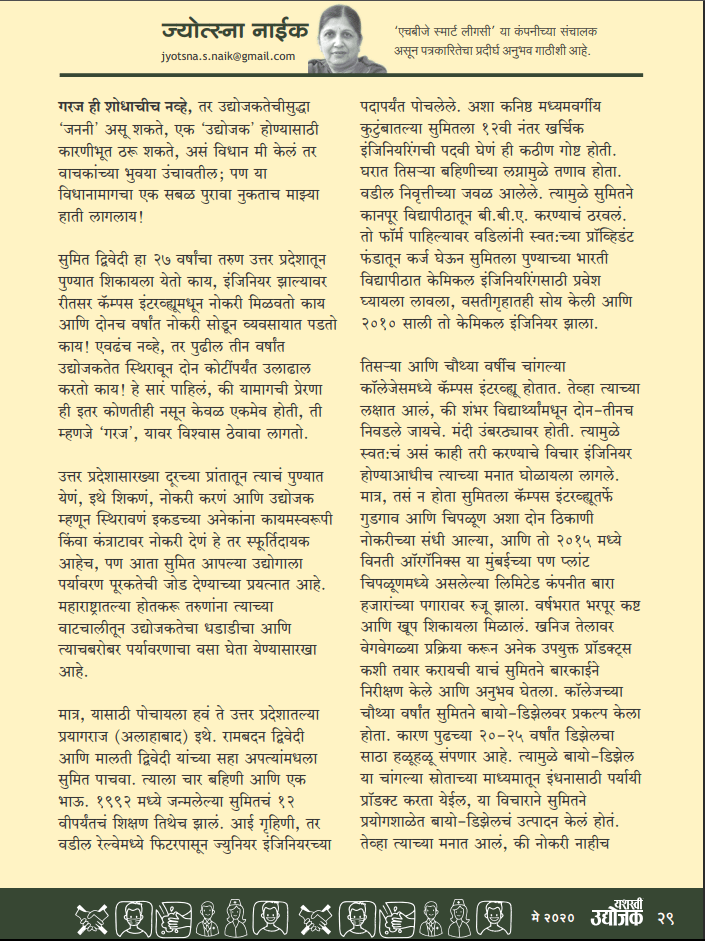

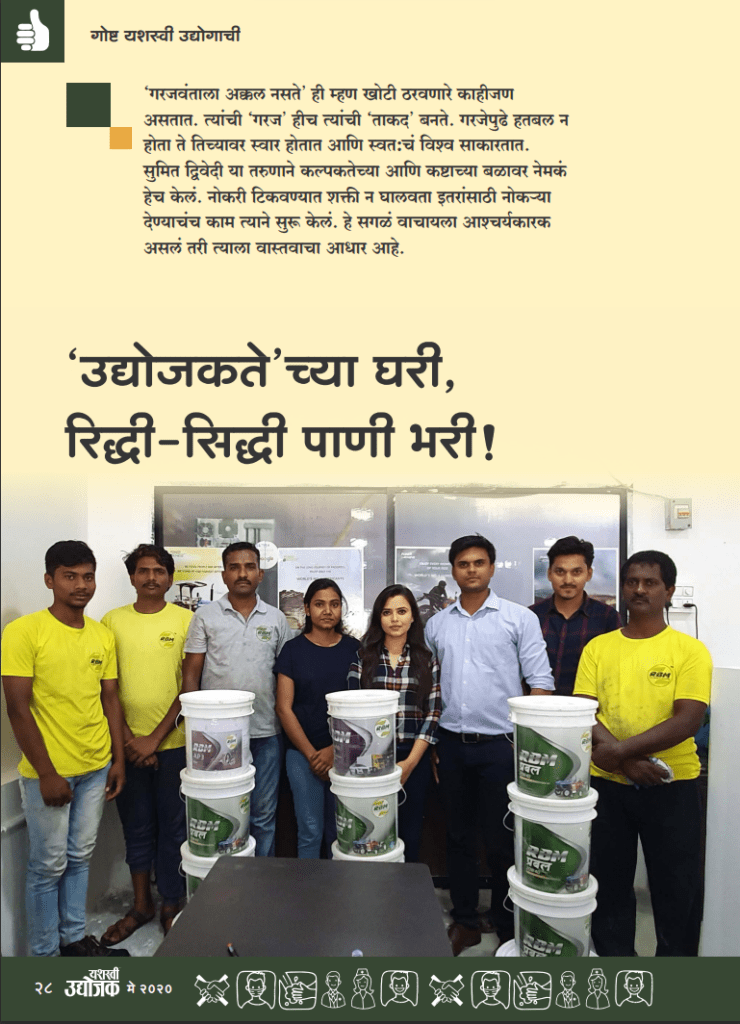

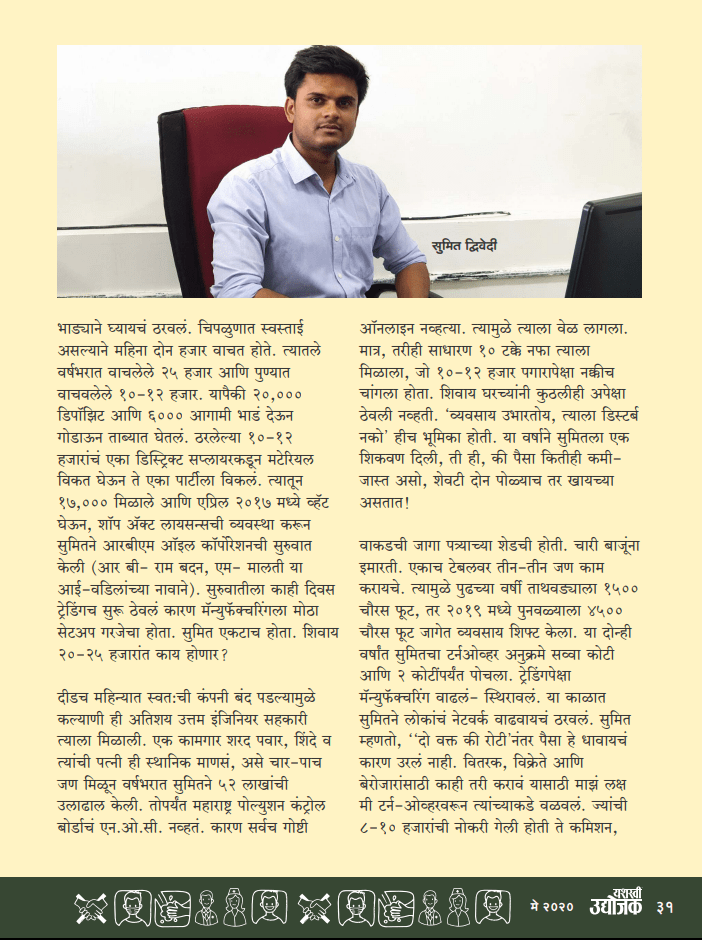

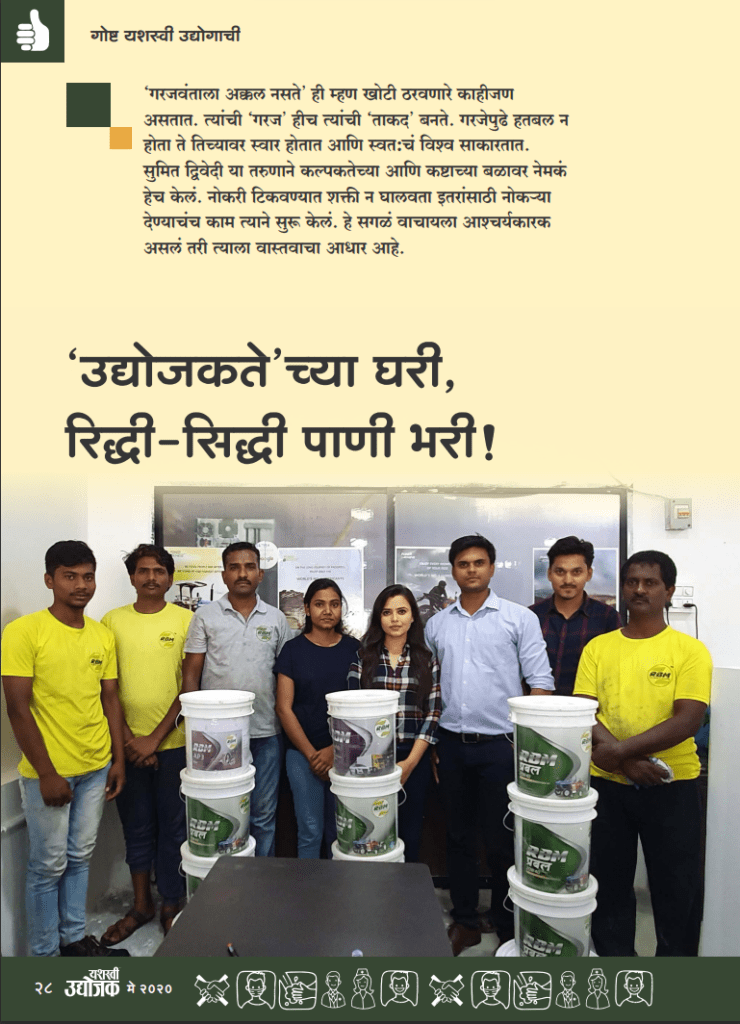

Here we shared some images related to our social presence like some coverage in the Maharashtrian Magazine last year and newspaper covering of some events organized by our distributors in Uttar Pradesh state of India.

Here we shared some images related to our social presence like some coverage in the Maharashtrian Magazine last year and newspaper covering of some events organized by our distributors in Uttar Pradesh state of India.

Industrial lubricants are specialized types of lubricants that are used in various industrial applications to reduce friction, heat, and wear between moving parts. They are designed to withstand high temperatures, heavy loads, and harsh operating conditions that are common in industrial machinery and equipment.

Here are some common types of industrial lubricants:

It’s important to note that the selection of the appropriate industrial lubricant depends on the specific application, equipment requirements, and operating conditions. Consulting with lubricant manufacturers or industry experts can help determine the best lubricant for a particular industrial application.

When selecting an industrial lubricant, factors such as operating temperature, load, speed, environmental conditions, and compatibility with equipment materials should be considered. It is crucial to follow the manufacturer’s recommendations and specifications for proper lubricant selection and maintenance practices to ensure optimal performance and equipment longevity.

Another unique feature of industrial lubricants is the use of nanotechnology. By using nanoparticles in lubricants, it allows for the lubricant to fill in the micro-pores and imperfections on the machinery surface which leads to better lubrication and protection. This results in lower friction and wear, as well as improved energy efficiency.

There are also specialized lubricants for specific industries such as food-grade lubricants, which are safe to use in food processing facilities and do not leave any harmful residue. In addition, there are also lubricants specially formulated for the mining industry to withstand the harsh conditions and extreme temperatures that mining equipment is exposed to.

Overall, industrial lubricants are a vital component in maintaining the smooth operation of machinery and equipment across various industries. With the advancements in technology and research, there are now more specialized and sustainable options available for industrial lubrication.

6 Profitable Business Ideas in oil and gas

1. Business Ideas

The oil and gas industry is considered one of the most profitable industries in today’s time. It is a global multifaceted industry that affects all aspects of our daily lives. Also, it is the employer for many people across the globe. Apart from this, it has vast growth potential in the future. After witnessing this growth potential, many new businesses and startups are keen to become part of the oil and gas markets. This has created cut-throat competition in the oil and gas business. However, you can still enter these markets, but how? To get the answer to this question, you need to read this blog. In this blog, we will show you six amazing business opportunities to earn huge profits in the oil and gas industry. 6 profitable business ideas for the oil and gas industry with deep planning and market research, anyone can start a business in the oil and gas industry and get growth opportunities. Here are the most profitable oil and gas business ideas for budding startups: On-demand fuel delivery fuel startups and businesses can consider venturing into the on-demand fuel delivery business to get high revenues. For this, they first have to make an advanced on-demand delivery solution for making fuel deliveries. Mostly, customers find it challenging to go to a petrol station for fuel.

There are several reasons for this such as long lines, distance, theft, insecure fuel handling, etc. However, you can help your customers by delivering fuel to their doorsteps with an on-demand fuel delivery solution. On-demand cooking gas delivery The on-demand cooking gas delivery business is also one of the lucrative opportunities in the oil and gas industry. Also, this business can be started with minimal investment compared to establishing a traditional gas station.

Most oil spills occur due to hazardous incidents that consist of refineries, tankers, storage facilities, pipelines

You can start offering on-demand cooking delivery services directly to the customers. Also, you can think of becoming a cooking gas aggregator by connecting cooking gas delivery operators to the end-users by creating an uber-like on-demand cooking gas delivery app. So just research the cooking gas delivery market in-depth and make a clear decision. Oil spillage cleaning oil spillage is the release of oil into the environment due to pollution or human errors. Oil spillage occurs on both water and land. Due to this, a lot of oil and gas companies are suffering from oil spillage. In the oil industry, mostly oil spills occur due to hazardous incidents that consist of refineries, tankers, storage facilities, pipelines, barrages, etc. These damages are the result of vandalization, sabotage, or operational damages. Now, you have an opportunity to earn good revenues by solving these oil spillage issues. So if you are looking for a business to start in the value chain of the oil and gas industry, then you can start with oil spillage cleaning. However, oil spillage cleaning requires a great skill set due to the risk involved. And if you are successful to get one oil spillage cleaning contract, then you would surely earn high returns. In oil and Gas consultancy nowadays, new oil delivery startups are looking for guidance, resources, and solid backing to excel in these markets. This has created a need for proper mentoring in the oil delivery market. Oil and gas consultancy is the best choice for those who are having vast experience and relevant qualifications. Oil and gas consulting is a lucrative business idea if you are having vast exposure to the oil and gas industry. However, you first need to get specialized training and education before starting a consultancy. Oil industry blogging another popular business idea is to start writing a blog about the oil and gas industry. It is interesting to note that many people in the markets are earning a good amount from blogging. So if you are having profound knowledge of the oil and gas industry then blogging on oil and gas-related subjects is a great idea. Also, if your blog consists of useful and helpful content, you will attract good visitor traffic to your blog. Due to this, you can easily fetch profitable advertising deals from stakeholders and other businesses. Just make sure that you update your blog regularly so that you continue to attract a higher number of traffic.Private oil refinery is one of the latest business ideas in the oil and gas industry. So if your country’s law allows opening a private oil refinery then you should consider opening your oil refinery.

For establishing a private refinery, you first need to acquire a license from the relevant ministries. Also, you need to maintain several safety measures as oil refining is a risky business. So by keeping the above things in mind, you can start your oil refinery. In conclusion, here we are with six attractive opportunities in the oil and gas industry.

By understanding these ideas in detail, you can decide on your next venture. But your task doesn’t get finished by just reading these ideas. Along with it, you need to gather a lot of information and understand the laws and regulations of the oil and gas industry. Moreover, if your business idea gets successful in gaining the attention of prime decision-makers in this field then you may successfully fetch the necessary funding. Also, you can increase your visibility in the oil and gas markets with the help of popular social media platforms.

So just grab any one of the abovementioned opportunities and start your journey towards success.

RBM OIL CORPORATION MANUFACTURER OF GREASE IN PUNE INDIA

a thick, oily lubricant consisting of inedible lard, the rendered fat of waste animal parts, or a petroleum-derived or synthetic oil containing a thickening agent.

White grease is made from inedible hog fat and has a low content of free fatty acids. The yellow shade is made from darker parts of the hog and may include parts used to make white shade. Brown contains beef and mutton fats as well as hog fats. Fleshing grease is the fatty material trimmed from hides and pelts. In some factories, food offal is used along with animal carcasses, butcher-shop scraps, and garbage from restaurants for the recovery of fats.

Greases of mineral or synthetic origin consist of a thickening agent dispersed in a liquid lubricant such as petroleum oil or a synthetic fluid. The thickening agent may be soap, an inorganic gel, or an organic substance. Other additives inhibit oxidation and corrosion, prevent wear, and change viscosity. The fluid component is the more important lubricant for clearances between parts that are relatively large, but for small clearances, the molecular soap layers provide lubrication.

tribology

the study of the interaction of sliding surfaces. It includes three subjects: friction, wear, and lubrication. There is a difficulty in that friction is generally characterized as a branch of physics or mechanical ENGINEERING, wear is part of the material science of metallurgy, while lubrication is a branch of chemistry. Tribology is thus a complex interdisciplinary subject.

The phenomena considered in tribology are among the most fundamental and most common of those encountered by humans in interaction with their largely solid environment. Many manifestations of tribology are beneficial and, indeed, make modern life possible. Many other effects of tribology, however, constitute serious nuisances, and careful design is necessary to overcome the inconvenience arising from excessive friction or wear. On an overall basis, friction uses up, or wastes, a substantial amount of the energy generated by mankind, while a large amount of productive capacity is devoted to replacing objects made useless by wear.

Friction has been studied as a branch of mechanics for many hundreds of years and its laws, as well as satisfactory methods of estimating the magnitude of friction, have been known for nearly two centuries. The mechanism of friction, namely, the exact process by which energy is lost as two surfaces slip past each other, is understood only in an incomplete way.

Wear is the removal of material from a solid surface as a result of the mechanical action exerted by another solid. It is such a universal phenomenon that rarely do two solid bodies slide over each other or even touch each other without measurable material transfer or material loss. Thus, coins become worn as a result of continued contact with human fingers; pencils become worn after sliding over the paper, and rails become worn as a result of the continued rolling of train wheels over them.

Only living things (e.g., bone joints) are in general immune to the permanent damage caused by wear because only they have the property of healing through regrowth. And even a few living things do not heal themselves (e.g., teeth in humans).

The systematic study of wear has been severely hampered by two factors: first, the existence of a number of separate wear processes, which has led to much confusion, especially in terminology; second, the difficulties caused by the small amounts of material involved in wear processes.

These difficulties were greatly alleviated when radioactive isotopes of the common engineering metals (iron, copper, chromium, etc.) became available in the 1940s; tracer techniques using these radioisotopes permit measurements of wear, even in small amounts, while it is occurring. This has made it possible to identify types of wear and discover the laws of wear.

Enter your contact details and get directly connected with our executives!