Extreme Pressure (EP) grease is a heavy-duty lubricant specifically formulated to withstand high loads, shock loading, and intense mechanical stress. It contains EP additives like sulfur-phosphorus compounds or molybdenum disulfide (MoS₂), which form a protective layer on metal surfaces to prevent wear, scuffing, and surface welding under extreme pressure conditions.

Purposes of Extreme Pressure Grease:

- Provides superior protection for heavily loaded bearings and gears in high-pressure environments.

- Forms a durable anti-wear film to prevent metal-to-metal contact under shock and impact loads.

- Maintains lubricating properties at elevated temperatures in continuous-duty operations.

- Minimizes component failure, unscheduled downtime, and costly repairs in critical equipment.

- Enhances equipment reliability in industrial, automotive, and construction

Uses of Extreme Pressure Grease:

- Used in lathe operations like turning, threading, and facing.

- Applied in drilling and tapping to reduce tool wear and breakage.

- Used during milling, grinding, and sawing to maintain surface quality and cooling.

- Employed in CNC machining and other precision processes for enhanced accuracy.

- Suitable for both manual and automatic machines in the metalworking industries.

Cutting oils come in various types, including straight oils, soluble oils (emulsions), synthetic, and semi-synthetic fluids, each suited for different materials and machining conditions.

Types of Extreme Pressure Grease:

- Construction and earthmoving equipment such as bulldozers, cranes, and excavators.

- Automotive drivetrain components, including CV joints, U-joints, and wheel bearings.

- Heavy-load industrial gear systems, couplings, and mechanical presses.

- Mining, steel, and cement industries where shock loading is frequent.

- Marine and rail equipment exposed to high-stress mechanical forces and vibration.

EPO

Packaging sizes: 18KG, 180KG

Uses: For heavy load bearings and industrial machinery.

EPOO

Packaging sizes: 18KG, 180KG

Uses: For shock load gears and construction equipment.

EPOO

Packaging sizes: 18KG, 180KG

Uses: For shock load gears and construction equipment.

EPOOO

Packaging sizes: 18KG, 180KG

Uses: For extreme load, slow-speed heavy machinery.

AP3 Lithium (Brown)

Packaging sizes: 100GM, 250GM, 500GM, 1KG, 5KG, 18KG, 180KG

Uses: For general-purpose automotive & industrial lubrication.

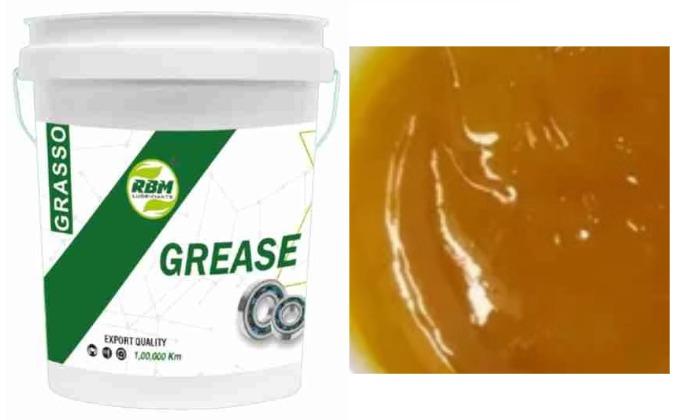

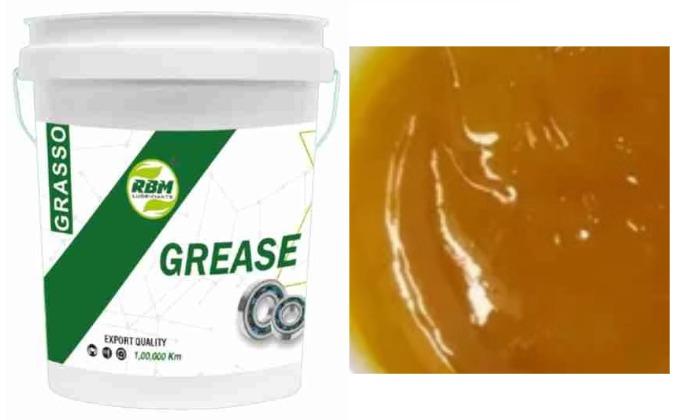

AP3 Lithium (Brown)

Packaging sizes: 100GM, 250GM, 500GM, 1KG, 5KG, 18KG, 180KG

Uses: For general-purpose automotive & industrial lubrication.

AP3 Moly

Packaging sizes: 18KG, 180KG

Uses: For high-load sliding parts in mining & construction equipment.

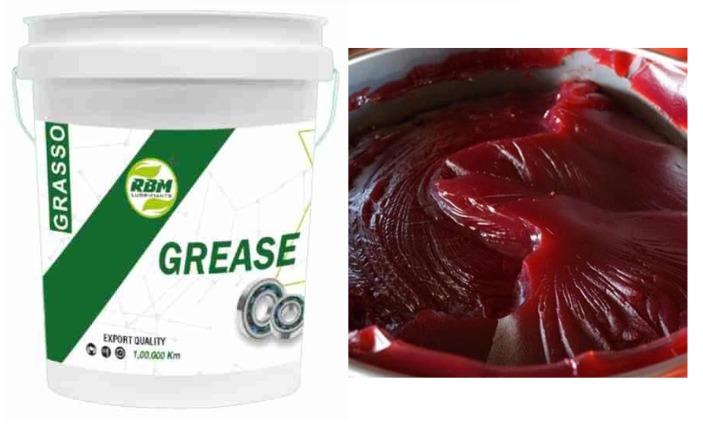

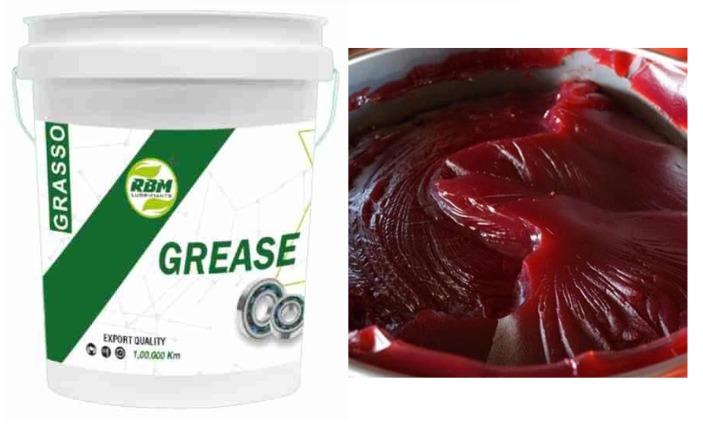

AP3 Lithium (Red)

Packaging sizes: 100GM, 250GM, 500GM, 1KG, 5KG, 18KG, 180KG

Uses: For general-purpose automotive & industrial lubrication.

AP3 Lithium (Red)

Packaging sizes: 100GM, 250GM, 500GM, 1KG, 5KG, 18KG, 180KG

Uses: For general-purpose automotive & industrial lubrication.

AP3 Lithium Complex 222 Titanium (Blue)

Packaging sizes: 18KG, 180KG

Uses: For high-temperature, long-life applications like wheel bearings & motors.

PD2

Packaging sizes: 18KG, 180 KG

Uses: For medium to heavy-duty machinery under moderate temperatures.

PD2

Packaging sizes: 18KG, 180 KG

Uses: For medium to heavy-duty machinery under moderate temperatures.

PD3

Packaging sizes: 18KG, 180 KG

Uses: For very heavy-duty, high-temperature continuous operations in steel, paper & mining industries.